Quantum Plating, Inc.

Quantum Plating, Inc.Request A Quote

Erie, PA | 814-835-9213https://www.quantumplating.com/

Quantum Plating, Inc., located in Erie, PA, is a leading company specializing in electroless nickel plating and providing comprehensive metal finishing solutions. With a strong presence in the industry, Quantum Plating has built a solid reputation for delivering exceptional electroless nickel plating services to customers across diverse sectors. Electroless nickel plating is a precise and controlled process that involves the deposition of a layer of nickel onto a substrate without the need for an electric current. This technique offers numerous advantages, including excellent corrosion resistance, wear resistance, and uniform coating thickness, making it highly suitable for a wide range of applications. Quantum Plating excels in its electroless nickel plating capabilities and offers a comprehensive range of services to meet the unique needs of its customers. The company utilizes state-of-the-art plating equipment and employs advanced techniques to ensure the highest quality and consistency in their plating processes. Their team of highly skilled technicians possesses extensive knowledge and expertise in electroless nickel plating, enabling them to handle complex projects and meet the precise requirements of each customer. The company provides a diverse selection of electroless nickel plating options tailored to specific applications. These options include low phosphorous, medium phosphorous, and high phosphorous coatings, each offering distinct properties such as hardness, corrosion resistance, and uniformity. Quantum Plating works closely with customers to understand their specific needs and provides customized solutions that meet their unique requirements. Quantum Plating places a strong emphasis on quality assurance. The company adheres to stringent industry standards and implements rigorous quality control measures throughout the plating process. They utilize advanced testing methods to ensure that the plated parts meet the highest standards of quality and performance, from the initial stages of pre-plating surface preparation to the final stages of post-plating inspections. In addition to their electroless nickel plating capabilities, Quantum Plating offers a range of value-added services to complement their metal finishing solutions. These services include surface preparation, masking, and passivation. With their expertise in handling various substrates, including metals and alloys, they cater to customers from diverse industries such as automotive, aerospace, electronics, and manufacturing. Quantum Plating is committed to delivering exceptional customer service. They prioritize customer satisfaction by offering quick turnaround times, competitive pricing, and personalized technical support. The company's dedicated team is readily available to address customer inquiries, provide expert advice, and ensure a seamless and successful plating process. In summary, Quantum Plating, Inc. is a trusted provider of electroless nickel plating services. With their advanced capabilities, state-of-the-art facilities, and commitment to quality, they have established themselves as a reliable partner for customers seeking high-quality metal finishing solutions in Erie, PA, and beyond.

Aluminum Anodizing

Aluminum Anodizing EDM

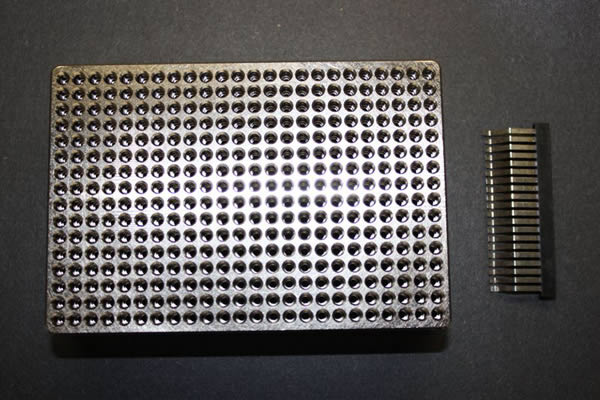

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services