Arlington Plating Company

Arlington Plating CompanyRequest A Quote

Palatine, IL | 847-359-1490https://www.arlingtonplating.com/

Arlington Plating Company, headquartered in Palatine, Illinois, is a reputable provider of electroless nickel plating solutions. With decades of experience and a commitment to excellence, Arlington Plating has established itself as a trusted partner for industries seeking high-quality and reliable electroless nickel plating services. Electroless nickel plating is a specialized process that involves the deposition of a uniform layer of nickel alloy onto various substrates. This coating provides exceptional corrosion resistance, wear resistance, and hardness, making it suitable for a wide range of applications. Arlington Plating specializes in delivering customized electroless nickel plating solutions tailored to meet the specific requirements of their customers. The team at Arlington Plating comprises highly skilled and knowledgeable professionals who possess expertise in electroless nickel plating processes. They work closely with customers to understand their unique needs, project specifications, and desired outcomes. By leveraging their technical proficiency, industry experience, and dedication to innovation, the team at Arlington Plating consistently delivers superior electroless nickel plating results. Arlington Plating operates a state-of-the-art facility equipped with advanced plating equipment and systems. Their cutting-edge technology enables precise control over critical plating parameters, such as bath composition, temperature, pH, and agitation. By ensuring strict adherence to process control measures, Arlington Plating consistently produces high-quality electroless nickel plated components. In addition to electroless nickel plating, Arlington Plating offers a comprehensive range of value-added services to enhance the performance and aesthetics of plated parts. These services may include pre-plating surface preparation, masking, post-plating finishes, and more. The company's expertise extends to various substrate materials, including steel, aluminum, copper, brass, and various alloys. Quality assurance is a top priority at Arlington Plating, and they employ stringent quality control measures at every stage of the plating process. The company adheres to industry best practices and standards, utilizing advanced inspection and testing methods to ensure the integrity and conformity of the plated components. Arlington Plating's commitment to quality is evident through their certifications and compliance with relevant industry standards. Arlington Plating places a strong emphasis on customer satisfaction and strives to build long-term partnerships with their clients. They prioritize effective communication, responsiveness, and exceptional customer service throughout the plating process. The company's dedicated team works closely with customers, providing technical support, guidance, and updates to ensure the successful completion of every project. With their extensive experience and expertise, Arlington Plating serves a diverse range of industries, including automotive, aerospace, electronics, medical, and more. Their electroless nickel plating solutions have been successfully applied to various components, including precision parts, molds, tooling, and other critical applications where durability, corrosion resistance, and precision are paramount. In summary, Arlington Plating Company is a trusted provider of electroless nickel plating services based in Palatine, Illinois. Through their state-of-the-art facility, skilled team, and unwavering commitment to quality, they deliver customized electroless nickel plating solutions that meet the unique requirements of their customers. Arlington Plating's dedication to quality control, exceptional customer service, and technical expertise make them a preferred partner in the electroless nickel plating industry.

Aluminum Anodizing

Aluminum Anodizing EDM

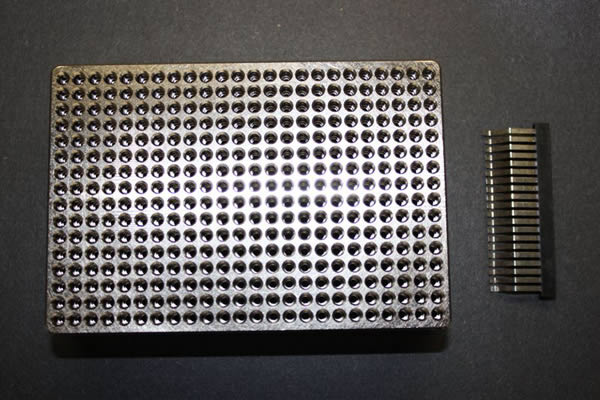

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services